When attaching a part under test to the Hydraulic Burst/Leak Tester (HBLT), the ideal method is a direct connection to the HBLT outlet port. However, when parts are in a safety enclosure or water bath, you must extend the hydraulic path from the HBLT outlet to the part. This usually means adding an extension tube to your fixture.

The main goal is to select tubing that does not affect the test results. The tubing must have sufficient inner diameter to allow some flow without a pressure drop. The tubing should have no or minimal compliance. In addition, any tubing must be easily purged if it is left in place for extended periods. Finally, keep the tubing length as short as possible. Overall tubing compliance worsens with length.

When using the HBLT with a Smart Manifold in parallel mode, take special precautions to insure the sum of the compliance of all ten extension tubes does not affect your test. Use the least compliant tubing and keep the lengths as short as possible.

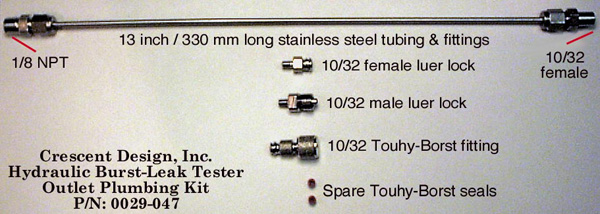

The ideal tubing is stainless steel tubing with compression fittings. If the flow demands are low, then smaller diameter tubing is easily bent into shapes and attached at both ends with compression fittings. Crescent Design sells an Outlet Plumbing Kit which provides the HBLT user with a quick and easy means for attaching product to the HBLT for testing. For higher flow rates, larger diameter tubing formed with multiple pieces or bent with tubing bending tools works well.

Plastic tubing that is sufficiently non-compliant also works as well. We have found that Qosina part number 33018 is a good substitute to stainless steel for some applications. It is made of two coextruded plastics that have little compliance but are flexible. This tubing works well with water baths where the parts are attached and then moved into the water bath for testing. The flexibility of the plastic is superior to the fixed shape stainless steel tubing in this application.

Avoid using braided steel high-pressure tubing. This tubing is extremely compliant until the inner rubber or plastic tube contacts the steel braid. This can affect the ramp rates because of the overall changing compliance characteristics.

If you need to evaluate your tubing selection, request the document Tubing Extension Sets Compliance Study from Crescent Design. This document details testing methods to insure a good tubing selection.